Business Challenge

A leading multinational telecom organization faced challenges with network downtime incidents and

high operational costs, largely due to inefficient spare part management for field repairs. Engineers

often arrived at sites without the correct spare parts, leading to multiple visits. Overall network field

operations accounted for ~60% of total operations cost.

The goal was to predict exact spare parts needed based on alarm triggers to enable single-visit

resolutions and reduce costs.

Our Solution

To address the above-mentioned challenges, the telecom company partnered with us to implement a

data driven spare parts recommendation solution.

AIQMEN developed a solution using Bayesian Inference Framework

to address this challenge. This probabilistic model moved beyond

traditional methods to accurately forecast spare parts, enabling

proactive field operations.

Solution steps :

1. Foundation

Our solution is built upon a rich dataset, providing critical insights

into historical operations:

- Incidents : 8000+ unique incidents with spare part usage over 3 years

- Spare Parts : 400+ distinct spare parts utilized

- Sites : Data collected from 3,000+ operational sites

- Alarms : ~400 unique alarm types recorded

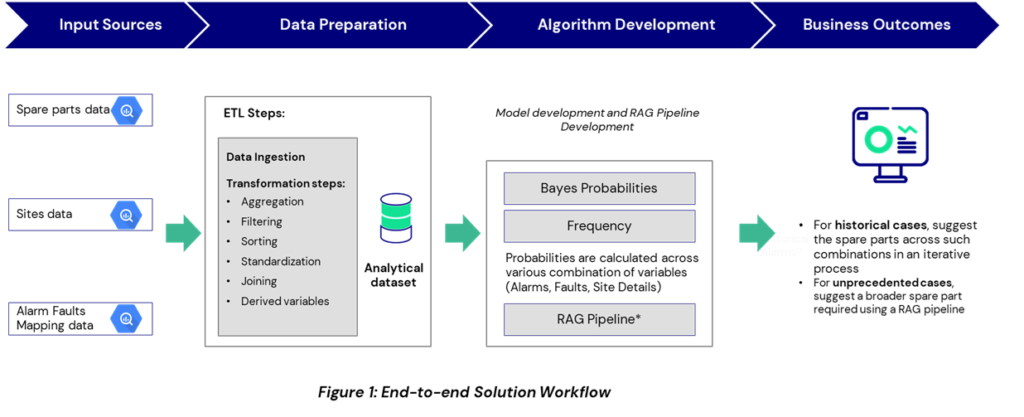

2. A streamlined AI-driven workflow

We developed a Bayesian Inference driven workflow processed entirely

on Google Cloud’s Vertex AI, leveraging data from Big Query. This ensured a scalable and efficient system

to deliver actionable recommendations to field engineers.

- Data Integration : Multi-year historical data, including spare parts usage, alarm logs, and operational metadata, was integrated. Both structured and unstructured fields, such as Fault and Unit Names (e.g., LANE, SFP), were utilized to identify patterns and create new variables.

- NLP based Feature Extraction : Text fields like Fault Codes, Unit Name, Site Frequency Bands, and Alert Communication were transformed into actionable variables using Natural Language Processing (NLP) techniques, enriching the model’s inputs.

- Probabilistic Lookup Framework : We applied a combination of Bayesian and frequency-based scoring to calculate robust probabilities across various feature combinations (e.g., alarms, site details, product categories), ensuring accurate predictions.

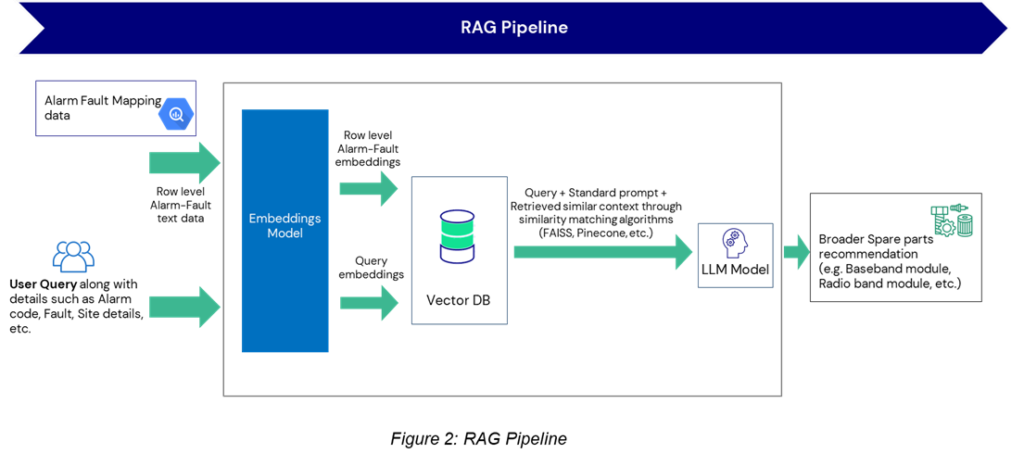

- Continuous Updates via RAG : An AI-driven Retrieval-Augmented Generation (RAG) pipeline continuously updated the model with the latest alarm and fault inventory data. This mechanism (as shown in Figure 2) ensures the system remains accurate and adaptable, especially for unprecedented cases not previously encountered by the probabilistic framework.

Key Outcomes

The implementation of AIQMEN's Bayesian Decision Intelligence System delivered significant,

measurable benefits, transforming the telecom company's field operations from reactive to proactive.

- High Accuracy for Known Patterns : The model achieved 95%+ accuracy in predicting spare parts when alarms and units matched historical patterns.

- Effective for New Scenarios : For less common issues, the system demonstrated strong performance, correctly identifying parts in approximately 80% of cases.

- Operational Efficiency : This led directly to fewer site visits, reduced downtime, and significant cost savings, alongside marked improvements in service reliability.

- Validation Set Robustness : Our 6 weeks validation set (with less than 2% overlap of existing spare parts and alarms) demonstrated strong generalization, confirming the model's predictive power on new data.

- Adaptability & Scalability : The integrated RAG pipeline ensures continuous model improvement and provides futureproofing, specifically addressing unprecedented cases.

- Strategic Shift : The solution enabled a fundamental shift from reactive repairs to a proactive, efficient operational model.

Broader Applicability

While developed for telecommunications, this Bayesian – RAG hybrid approach is highly adaptable

across industries where failure signals (e.g., alerts, logs, sensor data) can be mapped to specific

remediation actions. For instance:

- Manufacturing : Predicting machine parts for preventive maintenance

- Healthcare : Identifying probable diagnostic tests based on symptom patterns

- Logistics : Recommending spare SKUs for critical supply chain nodes

Found interesting! Want to discuss more? Let’s talk